औद्योगिक वोल्टेज उपकरण संयंत्रों को उपकरणों की विश्वसनीयता बनाए रखने और महंगी प्रणाली विफलताओं को रोकने में लगातार चुनौतियों का सामना करना पड़ता है। निर्माण संचालन में इष्टतम प्रदर्शन सुनिश्चित करने के लिए उन्नत परीक्षण और अनुकरण उपकरणों के एकीकरण आवश्यक हो गया है। ए प्रोग्रामेबल एसी पावर स्रोत उन सुविधाओं के लिए एक महत्वपूर्ण निवेश का प्रतिनिधित्व करता है जो अपनी गुणवत्ता नियंत्रण प्रक्रियाओं में सुधार करना चाहती हैं और अप्रत्याशित डाउनटाइम को कम करना चाहती हैं। ये परिष्कृत उपकरण विद्युत पैरामीटर पर सटीक नियंत्रण सक्षम करते हैं, जिससे इंजीनियर विभिन्न संचालन स्थितियों का अनुकरण कर सकते हैं और उत्पादन शेड्यूल प्रभावित होने से पहले संभावित समस्याओं की पहचान कर सकते हैं।

उत्पादन के वातावरण में उत्पाद की गुणवत्ता और संचालन दक्षता बनाए रखने के लिए विद्युत आपूर्ति विशेषताओं की निरंतरता की आवश्यकता होती है। पारंपरिक विद्युत आपूर्ति प्रणालियों में व्यापक उपकरण परीक्षण प्रोटोकॉल के लिए आवश्यक लचीलापन और सटीकता अक्सर अनुपस्थित होती है। आधुनिक प्रोग्रामेबल एसी पावर सोर्स तकनीक वोल्टेज, आवृत्ति और तरंग रूप विशेषताओं पर पूर्ण नियंत्रण प्रदान करके इन सीमाओं को दूर करती है। सामान्य संचालन या आपातकालीन स्थितियों के दौरान होने वाली विभिन्न विद्युत स्थितियों में उपकरण प्रदर्शन को मान्य करते समय यह क्षमता अमूल्य साबित होती है।

वोल्टेज उपकरण निर्माण में उपकरण विफलताओं के वित्तीय प्रभाव केवल तात्कालिक मरम्मत लागत तक सीमित नहीं हैं। उत्पादन में देरी, गुणवत्ता संबंधी समस्याएं और सुरक्षा चिंताएं समग्र लाभप्रदता और बाजार की प्रतिष्ठा को गंभीर रूप से प्रभावित कर सकती हैं। उन्नत प्रोग्रामेबल एसी पावर सोर्स उपकरण का उपयोग करके मजबूत परीक्षण प्रक्रियाओं को लागू करने से विकास चक्र के आरंभ में ही कमजोरियों की पहचान करने में मदद मिलती है। इस प्रो-एक्टिव दृष्टिकोण से निर्माताओं को उत्पादन मात्रा या ग्राहक संतुष्टि स्तर को प्रभावित करने से पहले संभावित समस्याओं को दूर करने की क्षमता मिलती है।

प्रोग्रामेबल एसी पावर सोर्स तकनीक की व्याख्या

मूल कार्यक्षमता और संचालन सिद्धांत

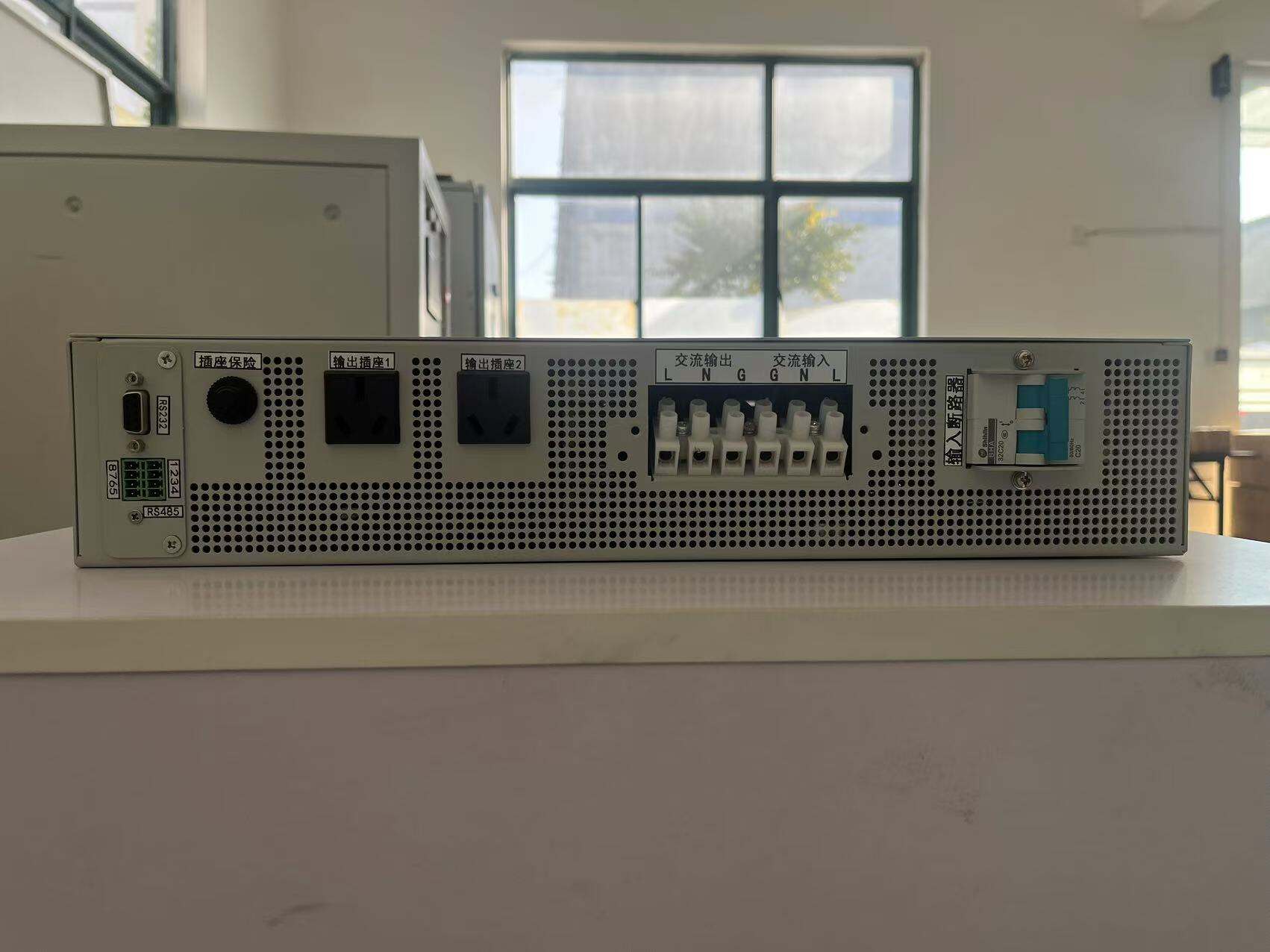

एक प्रोग्रामेबल एसी पावर स्रोत निर्दिष्ट विद्युत पैरामीटर के अनुरूप निर्गम संकेतों में निवेश शक्ति को परिवर्तित करके कार्य करता है। इन उपकरणों में उन्नत डिजिटल सिग्नल प्रोसेसिंग एल्गोरिथ्म का उपयोग कम विकृति के साथ स्वच्छ, स्थिर एसी तरंग रूप उत्पन्न करने के लिए किया जाता है। प्रोग्रामेबल प्रकृति के कारण उपयोगकर्ता विशिष्ट परीक्षण अनुप्रयोगों के लिए आवश्यक ठीक वोल्टेज स्तर, आवृत्ति सीमा और चरण संबंध निर्धारित कर सकते हैं। विभिन्न संचालन परिदृश्यों में उपकरण प्रदर्शन की पुष्टि करने के लिए इस लचीलेपन के कारण इन्हें अपरिहार्य उपकरण माना जाता है।

आधुनिक प्रोग्रामयोग्य एसी पावर स्रोत सिस्टम की आंतरिक वास्तुकी उच्च-गति स्विचिंग तत्वों और परिष्कृत नियंत्रण सर्किट्स को शामिल करती है। इन घटक विभिन्न लोड स्थितियों के तहत भी सटीक आउटपुट विशेषताओं को बनाए रखने के लिए साथ काम करते हैं। डिजिटल फीडबैक तंत्र लगातार आउटपुट मापदंडों की निगरानी करते हैं और सुसंगत प्रदर्शन सुनिश्चित करने के लिए वास्तविक समय में समानुरूपण करते हैं। इस स्तर की सटीकता इंजीनियरों को अपने परिणामों की शुद्धता में आत्मविश्वास के साथ पुनरावृत्त परीक्षण करने की अनुमति देती है।

उन्नत विशेषताएँ और नियंत्रण क्षमताएँ

समकालीन प्रोग्रामयोग्य एसी पावर स्रोत डिजाइन में कई ऐसी सुविधाएं शामिल हैं जो परीक्षण लचीलापन और संचालन सुविधा में वृद्धि करती हैं। दूरस्थ प्रोग्रामिंग क्षमताओं से स्वचालित परीक्षण अनुक्रमों को बिना किसी मानव हस्तक्षेप के निष्पादित किया जा सकता है। एकाधिक आउटपुट चैनलों से विभिन्न उपकरणों या सर्किट खंडों के समानुरूप परीक्षण की सुविधा मिलती है। हार्मोनिक जनरेशन कार्य औद्योगिक वातावरणों में सामान्यतः आने वाली बिजली गुणवत्ता संबंधी समस्याओं के अनुकरण की अनुमति देते हैं।

प्रोग्रामेबल एसी पावर स्रोत उपकरण में एकीकृत सुरक्षा सुविधाएँ परीक्षण उपकरणों और ऑपरेटरों को संभावित खतरनाक स्थितियों से बचाती हैं। अतिवोल्टता संरक्षण परिपथ अत्यधिक वोल्टता स्तरों से होने वाले नुकसान से बचाते हैं। धारा सीमित करने के कार्य लघु-परिपथ की स्थिति से सुरक्षा प्रदान करते हैं। आपातकालीन बंद करने की क्षमता असामान्य स्थितियों का पता चलने पर त्वरित प्रणाली अलगाव सुनिश्चित करती है। ये सुरक्षात्मक उपाय पारंपरिक विधियों की तुलना में प्रोग्रामेबल परीक्षण को अधिक सुरक्षित और विश्वसनीय बनाते हैं।

वोल्टता उपकरण परीक्षण में अनुप्रयोग

घटक सत्यापन और विश्लेषण

वोल्टेज डिवाइस के घटकों को उनके निर्धारित सेवा जीवन के दौरान विश्वसनीय संचालन सुनिश्चित करने के लिए विभिन्न विद्युत स्थितियों के तहत व्यापक परीक्षण की आवश्यकता होती है। एक प्रोग्रामेबल AC पावर स्रोत विभिन्न वोल्टेज और आवृत्ति सीमाओं में घटक व्यवहार के व्यापक चरित्र को समझने में सक्षम बनाता है। इस परीक्षण से ऐसे प्रदर्शन लक्षण प्रकट होते हैं जो नाममात्र संचालन स्थितियों के तहत स्पष्ट नहीं हो सकते। इंजीनियर व्यवस्थित परीक्षण प्रोटोकॉल के माध्यम से संचालन सीमाओं, तापीय व्यवहारों और दक्षता लक्षणों की पहचान कर सकते हैं।

घटक बुढ़ापे के अध्ययन को कार्यक्रम योग्य एसी पावर स्रोत क्षमताओं से काफी लाभ मिलता है। त्वरित जीवन परीक्षण के लिए उचित समय सीमा के भीतर सार्थक परिणाम उत्पन्न करने के लिए तनाव स्थितियों पर सटीक नियंत्रण की आवश्यकता होती है। परिवर्तनशील वोल्टेज और आवृत्ति परीक्षण विफलता मोड की पहचान करने और विभिन्न संचालन परिदृश्यों के तहत सेवा जीवन की भविष्यवाणी करने में सहायता करता है। यह जानकारी डिजाइन में सुधार के लिए मार्गदर्शन करती है और उत्पादन उपकरणों के लिए उचित सुरक्षा सीमाओं को स्थापित करने में सहायता करती है।

सिस्टम एकीकरण और संगतता परीक्षण

जटिल वोल्टेज उपकरण सिस्टम के घटकों की अंतःक्रियाओं और समग्र सिस्टम प्रदर्शन की पुष्टि की आवश्यकता होती है। प्रोग्रामेबल एसी पावर स्रोत उपकरण विभिन्न ग्रिड स्थितियों के अनुकरण को सक्षम करता है जो सिस्टम संचालन को प्रभावित कर सकती हैं। वोल्टेज सैग, सर्ज और हार्मोनिक विरूपण जैसे पावर गुणवत्ता मुद्दों को प्रणाली प्रतिक्रिया का मूल्यांकन करने के लिए व्यवस्थित रूप से लागू किया जा सकता है। यह परीक्षण वास्तविक संचालन वातावरण में तैनाती से पहले संभावित सुसंगतता समस्याओं को उजागर करता है।

एकीकरण परीक्षण प्रोटोकॉल को एक साथ कई विद्युत मापदंडों को सटीक रूप से नियंत्रित करने की क्षमता से लाभ मिलता है। प्रोग्रामेबल एसी पावर स्रोत सिस्टम बहु-चरण, भिन्न आवृत्तियों और ट्रांजिएंट स्थितियों से संबंधित जटिल परिदृश्यों का अनुकरण कर सकता है। इस व्यापक परीक्षण दृष्टिकोण से प्रणाली की कमजोरियों की पहचान करने में मदद मिलती है जिन्हें पारंपरिक परीक्षण विधियों के माध्यम से पता नहीं लगाया जा सकता। एकीकरण संबंधी समस्याओं का समय पर पता लगाना महंगी फील्ड विफलताओं और सेवा बाधाओं को रोकता है।

व्यवस्थित परीक्षण के माध्यम से विफलता की रोकथाम

डिज़ाइन की कमजोरियों का जल्दी पता लगाना

प्रोग्रामेबल एसी पावर स्रोत उपकरण का उपयोग करके व्यवस्थित परीक्षण उन डिज़ाइन कमजोरियों को उजागर करता है जो प्रारंभिक विकास चरणों के दौरान स्पष्ट नहीं हो सकतीं। चरम परिस्थितियों में तनाव परीक्षण उपकरणों के उत्पादन चरणों तक पहुँचने से पहले संभावित विफलता के बिंदुओं को उजागर करता है। इस जल्दी पहचान के कारण निर्माण शेड्यूल में बाधा डाले बिना डिज़ाइन में संशोधन किए जा सकते हैं। परीक्षण स्थितियों को सटीक रूप से नियंत्रित करने की क्षमता यह सुनिश्चित करती है कि सभी महत्वपूर्ण परिदृश्यों का व्यापक रूप से मूल्यांकन किया जाए।

प्रोग्रामेबल एसी पावर स्रोत सिस्टम द्वारा प्रदान की गई पुनरावृत्ति योग्यता और सटीकता के कारण डिज़ाइन वैधीकरण प्रोटोकॉल को लाभ मिलता है। डिज़ाइन की मजबूती को सत्यापित करने के लिए समान परिस्थितियों में कई बार परीक्षण किए जा सकते हैं। परीक्षण परिणामों का सांख्यिकीय विश्लेषण डिज़ाइन मार्जिन और अपेक्षित प्रदर्शन विशेषताओं में आत्मविश्वास प्रदान करता है। इस प्रणालीगत दृष्टिकोण से फील्ड विफलताओं और संबंधित वारंटी लागतों की संभावना कम हो जाती है।

गुणवत्ता आश्वासन और उत्पादन परीक्षण

उत्पादन परीक्षण की आवश्यकताओं को उत्पाद की गुणवत्ता सुनिश्चित करने के लिए स्थिर और विश्वसनीय परीक्षण परिस्थितियों की आवश्यकता होती है। गुणवत्ता आश्वासन कार्यक्रमों के लिए प्रभावी ढंग से काम करने हेतु प्रोग्रामेबल एसी पावर स्रोत उपकरण आवश्यक स्थिरता और सटीकता प्रदान करते हैं। महत्वपूर्ण मापदंडों का त्वरित और सटीक मूल्यांकन करने के लिए स्वचालित परीक्षण अनुक्रमों को प्रोग्राम किया जा सकता है। यह स्वचालन मैनुअल परीक्षण विधियों की तुलना में परीक्षण समय को कम करता है और परिणामों की स्थिरता में सुधार करता है।

प्रोग्रामेबल एसी पावर स्रोत सिस्टम द्वारा प्रदान की गई सटीकता से सांख्यिकी प्रक्रिया नियंत्रण कार्यक्रम को लाभ मिलता है। स्थिर परीक्षण परिस्थितियों से उत्पादन में भिन्नताओं और प्रवृत्तियों की सटीक ट्रैकिंग संभव होती है। प्रक्रिया में विचलन का समय रहते पता लगाने से ग्राहक शिपमेंट को प्रभावित किए बिना गुणवत्ता समस्याओं को रोका जा सकता है। इस प्रकार की प्रो-एक्टिव गुणवत्ता प्रबंधन दृष्टिकोण से क्षेत्र में विफलता दर में कमी आती है और ग्राहक संतुष्टि स्तर में वृद्धि होती है।

आर्थिक लाभ और निवेश पर वापसी

कम विकास लागत और बाजार तक पहुंचने का समय

प्रोग्रामेबल एसी पावर स्रोत तकनीक में निवेश आमतौर पर कम विकास लागत और त्वरित उत्पादन शुरूआत के माध्यम से महत्वपूर्ण रिटर्न उत्पन्न करता है। डिजाइन संबंधी मुद्दों की समय रहते पहचान से महंगे पुनर्डिजाइन चक्र और उत्पादन विराम को रोका जा सकता है। व्यापक परीक्षण क्षमताओं से कई प्रोटोटाइप पुनरावृत्तियों की आवश्यकता कम हो जाती है। इस दक्षता में सुधार से कंपनियों को बाजार की अवसरों और प्रतिस्पर्धी दबावों के प्रति अधिक त्वरित प्रतिक्रिया करने की अनुमति मिलती है।

प्रोग्रामेबल एसी पावर स्रोत उपकरण की बहुमुखी प्रकृति इसे कई उत्पाद लाइनों और विकास परियोजनाओं में उपयोग करने में सक्षम बनाती है। इस साझा उपयोग से उपकरण के मूल्य को अधिकतम किया जाता है और प्रति परियोजना परीक्षण लागत कम होती है। उन्नत सुविधाएँ और स्वचालन क्षमताएँ परीक्षण दक्षता में सुधार करती हैं और श्रम आवश्यकताओं को कम करती हैं। ये संचालन सुधार तेज़ विकास चक्रों और बेहतर परियोजना लाभप्रदता में योगदान देते हैं।

वारंटी लागत में कमी और ग्राहक संतुष्टि

फ़ील्ड में विफलताओं के कारण वारंटी लागत में भारी वृद्धि होती है और कंपनी की प्रतिष्ठा को नुकसान का खतरा रहता है। प्रोग्रामेबल एसी पावर स्रोत परीक्षण ग्राहकों तक उत्पाद पहुँचने से पहले संभावित विफलता के तरीकों की पहचान करने में मदद करता है। इस रोकथाम दृष्टिकोण से वारंटी दावों की दर और संबंधित सेवा लागत में भारी कमी आती है। उत्पाद की बेहतर विश्वसनीयता ग्राहक संतुष्टि में सुधार करती है और प्रीमियम मूल्य निर्धारण रणनीतियों का समर्थन करती है।

व्यापक प्रोग्रामेबल एसी पावर स्रोत परीक्षण के माध्यम से प्राप्त बढ़ी विश्वसनीयता से दीर्घकालिक ग्राहक संबंधों को लाभ मिलता है। कम सेवा आवश्यकताओं और बढ़ी उत्पाद जीवन चक्र से ग्राहक वफादारी मजबूत होती है। सकारात्मक ग्राहक अनुभव संदर्भ उत्पन्न करते हैं और बाजार विस्तार प्रयासों का समर्थन करते हैं। ये संबंध लाभ अक्सर कम वारंटी लागत से प्रत्यक्ष वित्तीय रिटर्न से अधिक होते हैं।

लागू करने की रणनीतियाँ और बेहतरीन अभ्यास

उपकरण चयन और विशिष्टता

उपयुक्त प्रोग्रामेबल एसी पावर स्रोत उपकरण का चयन वर्तमान और भावी परीक्षण आवश्यकताओं पर विचार करने की आवश्यकता है। वोल्टेज और करंट सीमाएं मौजूदा उत्पादों को समाप्त करनी चाहिए जबकि भावी विकास के लिए हैडरूम प्रदान करनी चाहिए। आवृत्ति क्षमताओं को सभी प्रासंगिक संचालन शर्तों और मानक अनुपालन आवश्यकताओं को कवर करना चाहिए। परीक्षण प्रोटोकॉल आवश्यकताओं को पूरा करने या उससे अधिक करने के लिए सटीकता विर्फानियां अर्थपूर्ण परिणाम सुनिश्चित करने के लिए आवश्यक हैं।

उन्नत सुविधाओं का मूल्यांकन परीक्षण दक्षता और क्षमता में उनके योगदान के आधार पर किया जाना चाहिए। दूरस्थ प्रोग्रामिंग इंटरफेस स्वचालन एकीकरण को सक्षम करते हैं और मैनुअल संचालन को कम करते हैं। बहुआउटपुट चैनल समानांतर परीक्षण और बेहतर थ्रूपुट का समर्थन करते हैं। हार्मोनिक जनरेशन क्षमता वास्तविक परिचालन स्थितियों के अनुकरण की अनुमति देती है। इन सुविधाओं को परीक्षण प्रभावशीलता और संचालन दक्षता पर उनके प्रभाव के आधार पर प्राथमिकता दी जानी चाहिए।

मौजूदा परीक्षण प्रणालियों के साथ एकीकरण

प्रोग्रामेबल एसी पावर स्रोत उपकरण के सफल कार्यान्वयन के लिए मौजूदा परीक्षण बुनियादी ढांचे और प्रक्रियाओं के साथ सावधानीपूर्वक एकीकरण की आवश्यकता होती है। संचार इंटरफेस वर्तमान डेटा अधिग्रहण और नियंत्रण प्रणालियों के साथ संगत होने चाहिए। मौजूदा परीक्षण प्रोटोकॉल का समर्थन करते हुए सॉफ्टवेयर एकीकरण सुविधाओं को बढ़ावा देना चाहिए। कर्मचारी प्रशिक्षण कार्यक्रम नई उपकरण सुविधाओं और कार्यों के प्रभावी उपयोग को सुनिश्चित करते हैं।

धीरे-धीरे कार्यान्वयन रणनीतियाँ अक्सर पूर्ण प्रणाली प्रतिस्थापन की तुलना में अधिक प्रभावी साबित होती हैं। पायलट कार्यक्रम पूर्ण पैमाने पर तैनाती से पहले प्रोग्रामेबल एसी पावर स्रोत के लाभों का मूल्यांकन करने की अनुमति देते हैं। प्रारंभिक कार्यान्वयन के दौरान प्राप्त अनुभव बाद के स्थापन और अनुकूलन प्रयासों का मार्गदर्शन करता है। इस सावधान दृष्टिकोण से कार्यान्वयन के जोखिम कम होते हैं और तकनीकी निवेश से दीर्घकालिक लाभ अधिकतम होते हैं।

सामान्य प्रश्न

वोल्टेज उपकरण परीक्षण के लिए एक प्रोग्रामेबल एसी पावर स्रोत को किन वोल्टेज और आवृत्ति सीमाओं को कवर करना चाहिए?

अधिकांश औद्योगिक अनुप्रयोगों के लिए प्रोग्रामेबल एसी पावर स्रोत उपकरण की आवश्यकता होती है जो डीसी से लेकर कई किलोहर्ट्ज़ तक की आवृत्ति सीमा के साथ 0 से 300V एसी तक वोल्टेज उत्पन्न करने में सक्षम हो। विशिष्ट आवश्यकताएँ परीक्षणाधीन उपकरणों के प्रकार और लागू उद्योग मानकों पर निर्भर करती हैं। कुछ अनुप्रयोगों के लिए उच्च वोल्टेज क्षमता की आवश्यकता हो सकती है, जबकि परीक्षण प्रोटोकॉल और सटीकता विनिर्देशों के आधार पर सटीकता आवश्यकताएँ भिन्न होती हैं।

एक प्रोग्रामेमेबल एसी पावर स्रोत पारंपरिक तरीकों की तुलना में परीक्षण सटीकता को कैसे सुधारता है

प्रोग्रामेमेबल एसी पावर स्रोत प्रणालियां आउटपुट पैरामीटर के सटीक डिजिटल नियंत्रण और वास्तविक समय प्रतिक्रिया सुधार के माध्यम से उत्कृष्ट सटीकता प्रदान करती हैं। पारंपरिक तरीकों में अक्सर वोल्टेज नियमन की समस्याएं, आवृत्ति अस्थिरता और आकारांतरण विरूपण होता है जो परीक्षण परिणामों को प्रभावित कर सकता है। प्रोग्रामेमेबल प्रकृति परीक्षण सेटअप में मानव त्रुटि को खत्म कर देती है जबकि कई परीक्षण पुनरावृत्तियों में स्थिर परिस्थितियों की गारंटी देती है।

प्रोग्रामेमेबल एसी पावर स्रोत परीक्षण लागू करने के समय कौन से सुरक्षा विचार महत्वपूर्ण हैं

सुरक्षा कार्यान्वयन के लिए उचित भू-संपर्कन प्रणाली, आपातकालीन बंद प्रक्रियाएं और कर्मचारी सुरक्षा उपकरण की आवश्यकता होती है। प्रोग्रामेबल एसी पावर स्रोत उपकरण में अतिवोल्टता सीमन, धारा निगरानी और दोष का पता लगाने जैसी आंतरिक सुरक्षा सुविधाएं शामिल होनी चाहिए। कर्मचारियों के प्रशिक्षण में परीक्षण संचालन के दौरान सुरक्षित संचालन प्रक्रियाओं, आपातकालीन प्रतिक्रिया प्रोटोकॉल और व्यक्तिगत सुरक्षा उपकरण के उचित उपयोग को शामिल करना चाहिए।

उत्पादन वातावरण के लिए प्रोग्रामेबल एसी पावर स्रोत परीक्षण को कैसे स्वचालित किया जा सकता है

स्वचालन एकीकरण में आमतौर पर मानक संचार इंटरफेस के माध्यम से कंप्यूटरीकृत परीक्षण प्रणालियों के साथ कार्यक्रम योग्य AC बिजली स्रोत उपकरण को जोड़ना शामिल होता है। परीक्षण अनुक्रमों को न्यूनतम ऑपरेटर हस्तक्षेप के साथ स्वचालित रूप से निष्पादित करने के लिए कार्यक्रमित किया जा सकता है। डेटा लॉगिंग क्षमता परीक्षण परिणामों के स्वचालित दस्तावेजीकरण और सांख्यिकीय विश्लेषण को सक्षम करती है। यह स्वचालन दृष्टिकोण परीक्षण स्थिरता में सुधार करता है, साथ ही श्रम लागत और मानव त्रुटि की संभावनाओं को कम करता है।

विषय सूची

- प्रोग्रामेबल एसी पावर सोर्स तकनीक की व्याख्या

- वोल्टता उपकरण परीक्षण में अनुप्रयोग

- व्यवस्थित परीक्षण के माध्यम से विफलता की रोकथाम

- आर्थिक लाभ और निवेश पर वापसी

- लागू करने की रणनीतियाँ और बेहतरीन अभ्यास

-

सामान्य प्रश्न

- वोल्टेज उपकरण परीक्षण के लिए एक प्रोग्रामेबल एसी पावर स्रोत को किन वोल्टेज और आवृत्ति सीमाओं को कवर करना चाहिए?

- एक प्रोग्रामेमेबल एसी पावर स्रोत पारंपरिक तरीकों की तुलना में परीक्षण सटीकता को कैसे सुधारता है

- प्रोग्रामेमेबल एसी पावर स्रोत परीक्षण लागू करने के समय कौन से सुरक्षा विचार महत्वपूर्ण हैं

- उत्पादन वातावरण के लिए प्रोग्रामेबल एसी पावर स्रोत परीक्षण को कैसे स्वचालित किया जा सकता है