Modern laboratories face increasing demands for precise, high-current testing across diverse applications, from electric vehicle battery validation to advanced materials research. The backbone of these critical operations lies in sophisticated laboratory test power supplies that deliver exceptional performance while maintaining stringent safety protocols. These specialized instruments must provide stable, controllable power output while protecting both equipment and personnel from potentially dangerous electrical conditions during demanding test scenarios.

High-current testing presents unique challenges that require specialized solutions beyond conventional power sources. Laboratory environments demand equipment capable of delivering hundreds or thousands of amperes while maintaining precise voltage regulation and current control. The complexity increases when considering the thermal management, electrical isolation, and safety interlocks necessary to operate such powerful systems safely within research facilities.

Advanced Safety Features in High-Current Laboratory Power Systems

Comprehensive Protection Mechanisms

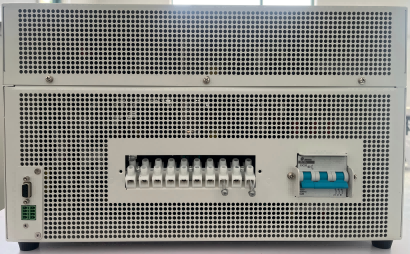

Modern laboratory test power supplies incorporate multiple layers of protection to prevent equipment damage and ensure operator safety during high-current operations. Overcurrent protection circuits monitor output continuously, instantly shutting down the system when predetermined thresholds are exceeded. Thermal monitoring sensors track internal temperatures across critical components, preventing dangerous overheating conditions that could compromise system integrity or create fire hazards.

Voltage protection systems work in conjunction with current monitoring to detect abnormal conditions such as short circuits, ground faults, or load impedance changes. These sophisticated protection schemes respond within microseconds, far faster than traditional circuit breakers or fuses. Arc fault detection technology identifies dangerous arcing conditions that might occur in high-current pathways, immediately isolating the affected circuits to prevent equipment damage or personnel injury.

Isolation and Grounding Strategies

Electrical isolation becomes critically important when dealing with high-current laboratory applications, where even small ground potential differences can create dangerous conditions. Advanced laboratory test power supplies utilize sophisticated isolation transformers and optical coupling technologies to maintain complete electrical separation between control circuits and high-power output stages. This isolation prevents ground loops and reduces the risk of electrical shock to operators.

Proper grounding infrastructure requires careful attention to conductor sizing, connection integrity, and impedance characteristics. High-current systems generate significant electromagnetic fields that can interfere with sensitive measurement equipment or create safety hazards if not properly managed. Equipment grounding conductors must be sized appropriately for fault current levels, while functional grounding ensures proper operation of protection systems and reduces electromagnetic interference.

Thermal Management and Environmental Considerations

Heat Dissipation Strategies

High-current laboratory operations generate substantial amounts of heat that must be effectively managed to maintain safe operating conditions and ensure reliable performance. Advanced cooling systems incorporate forced air circulation, liquid cooling loops, and heat sink technologies designed specifically for laboratory environments. Temperature monitoring systems continuously track thermal conditions throughout the power supply, providing early warning of potential overheating situations.

Thermal design considerations extend beyond the power supply itself to include ambient laboratory conditions, ventilation requirements, and heat load calculations for facility HVAC systems. Proper thermal management prevents component degradation, maintains calibration accuracy, and extends equipment lifespan while ensuring safe operating temperatures for laboratory personnel. Smart thermal control algorithms adjust cooling system operation based on load conditions, optimizing energy efficiency while maintaining optimal operating temperatures.

Environmental Safety Protocols

Laboratory environments require specialized considerations for high-current power supply installation and operation. Proper ventilation systems must handle both heat dissipation and potential gas emissions from high-current switching operations. Fire suppression systems need modification to address electrical fire risks associated with high-power equipment, including specialized suppression agents suitable for energized electrical equipment.

Electromagnetic compatibility becomes increasingly important as current levels rise, requiring careful attention to shielding, filtering, and conductor routing. Laboratory test power supplies must meet strict EMC requirements to prevent interference with sensitive measurement equipment while operating safely in close proximity to other laboratory instruments. Proper cable management and shielding techniques minimize electromagnetic emissions and reduce susceptibility to external interference.

Precision Control and Measurement Capabilities

Advanced Current Regulation Technologies

High-current testing demands exceptional precision and stability from laboratory power supplies, requiring sophisticated control algorithms and feedback systems. Modern current regulation technologies utilize digital signal processing and advanced control loops to maintain precise output characteristics even under rapidly changing load conditions. These systems provide measurement accuracy typically within 0.1% of full scale, enabling reliable data collection for critical research applications.

Programmable current slew rate control allows researchers to precisely control the rate of current change during testing sequences, preventing damage to sensitive test specimens while maintaining accurate test conditions. Advanced current measurement systems incorporate high-precision current shunts or Hall effect sensors that provide real-time feedback for closed-loop control while maintaining electrical isolation for safety.

Integration with Laboratory Information Systems

Modern laboratory test power supplies feature comprehensive communication interfaces that enable seamless integration with laboratory information management systems and automated test equipment. Ethernet, USB, and specialized laboratory communication protocols allow remote monitoring and control while maintaining detailed data logging capabilities. This connectivity enables automated test sequences while providing comprehensive documentation for regulatory compliance and quality assurance purposes.

Safety interlocks can be integrated with laboratory access control systems, ensuring that high-current testing operations are properly authorized and supervised. Remote monitoring capabilities allow laboratory managers to oversee high-current operations from secure locations while maintaining full control over safety systems and emergency shutdown procedures.

Regulatory Compliance and Standards

International Safety Standards

Laboratory test power supplies must comply with numerous international safety standards that govern high-current electrical equipment in research environments. IEC 61010 standards specifically address safety requirements for electrical equipment used for measurement, control, and laboratory use, providing comprehensive guidelines for design, installation, and operation of high-current systems. UL and CSA standards provide additional requirements for North American installations, ensuring compatibility with local electrical codes and safety practices.

Electromagnetic compatibility standards such as IEC 61326 establish limits for electromagnetic emissions and immunity requirements for laboratory equipment. These standards ensure that high-current power supplies operate safely without interfering with other laboratory instruments or being susceptible to external electromagnetic disturbances that could compromise safety or performance.

Laboratory Certification Requirements

Many laboratory applications require specific certifications or qualifications for high-current testing equipment, particularly in regulated industries such as automotive, aerospace, or medical device manufacturing. ISO 17025 accreditation may require detailed documentation of power supply calibration, traceability, and measurement uncertainty for laboratory test power supplies used in accredited testing procedures.

Quality management systems often mandate regular calibration and verification procedures for high-current power supplies, ensuring continued accuracy and safety throughout their operational lifetime. These requirements drive the need for comprehensive documentation, calibration procedures, and maintenance protocols that maintain equipment performance while ensuring ongoing compliance with applicable standards.

FAQ

What current levels are considered high-current in laboratory applications

High-current laboratory applications typically involve currents exceeding 100 amperes, though the definition varies by application and industry. Battery testing, electroplating research, and materials testing often require currents ranging from several hundred to several thousand amperes. The key distinction lies not just in current magnitude but in the precision, control, and safety requirements that distinguish laboratory applications from industrial power applications.

How do laboratory test power supplies prevent arc flash incidents during high-current operations

Modern laboratory test power supplies incorporate arc detection systems that monitor for the characteristic light, current, and voltage signatures of electrical arcing. When detected, these systems immediately interrupt the circuit using high-speed electronic switching or mechanical contactors. Additionally, proper personal protective equipment, restricted access zones, and remote operation capabilities help protect personnel from potential arc flash hazards during high-current testing.

What maintenance procedures are essential for high-current laboratory power supplies

Regular maintenance includes inspection of electrical connections for signs of overheating or corrosion, cleaning of cooling systems and air filters, verification of safety interlock operation, and calibration of current and voltage measurements. Thermal imaging surveys help identify developing problems before they create safety hazards. Documentation of all maintenance activities is essential for regulatory compliance and ensuring continued safe operation.

Can laboratory test power supplies be used for both DC and AC high-current testing

Many advanced laboratory test power supplies offer both DC and AC output capabilities, though the specific requirements for AC testing often require specialized features such as arbitrary waveform generation, power factor control, and harmonic analysis capabilities. Bidirectional power supplies can both source and sink power, enabling testing of energy storage devices and regenerative systems while maintaining the same safety and precision standards required for laboratory applications.

Table of Contents

- Advanced Safety Features in High-Current Laboratory Power Systems

- Thermal Management and Environmental Considerations

- Precision Control and Measurement Capabilities

- Regulatory Compliance and Standards

-

FAQ

- What current levels are considered high-current in laboratory applications

- How do laboratory test power supplies prevent arc flash incidents during high-current operations

- What maintenance procedures are essential for high-current laboratory power supplies

- Can laboratory test power supplies be used for both DC and AC high-current testing