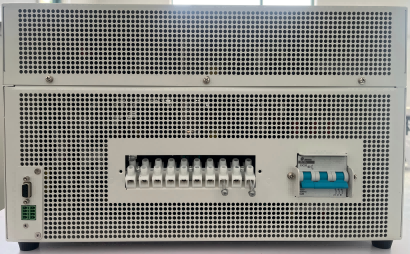

highprecision power supply

A high-precision power supply represents a sophisticated piece of electronic equipment designed to deliver exceptionally stable and accurate electrical power output. These advanced devices maintain precise voltage and current levels with minimal fluctuations, typically achieving accuracy rates of 0.1% or better. They incorporate advanced feedback mechanisms and digital controls to continuously monitor and adjust output parameters, ensuring consistent performance even under varying load conditions. The unit features multiple protection systems, including over-voltage, over-current, and short-circuit protection, safeguarding both the power supply and connected devices. Modern high-precision power supplies often include programmable features, allowing users to set specific voltage and current parameters, create custom output sequences, and store multiple configurations. They typically offer multiple output ranges and operating modes, including constant voltage, constant current, and sometimes constant power modes. These devices find essential applications in semiconductor testing, research laboratories, medical equipment calibration, and precision manufacturing processes where power stability is crucial for accurate results and reliable operation.